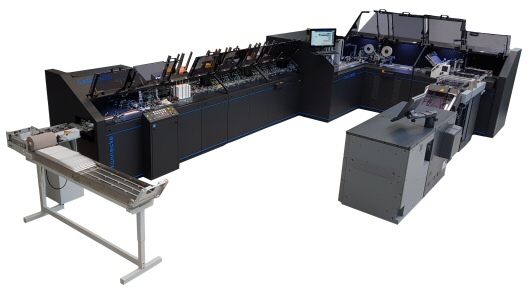

The flagship model of the Kuennecke range of secure card attaching and mailing systems is the MAILok C8000, capable of processing up to 8,000 cards per hour with up to four cards affixed per carrier document. Its predecessor, the C6000, is an industry favourite with over 120 global installations. Designed to run in a 24/7 high capacity environment, the C8000 is the number one choice for secure and efficient high volume card fulfilment.